This manual provides essential guidance for operating, maintaining, and troubleshooting the Onan 4000 Genset. It covers safety, technical specifications, installation, and optimal usage procedures.

1.1 Overview of the Onan 4000 Genset

The Onan 4000 Genset is a compact, lightweight, and quiet power generation solution designed for RVs and portable applications. It operates on gasoline, offering reliable performance for recreational and emergency power needs. The genset features a robust engine and advanced noise-reduction technology, making it ideal for residential and outdoor use. With a user-friendly design, it ensures easy operation and maintenance. The manual provides detailed instructions for safe installation, operation, and troubleshooting, ensuring optimal performance and longevity. This overview highlights the key aspects of the Onan 4000 Genset, emphasizing its suitability for diverse power requirements while maintaining efficiency and reliability.

1.2 Key Features and Benefits

The Onan 4000 Genset is renowned for its quiet operation, high efficiency, and durability. It features advanced MicroLite technology, which minimizes noise and enhances performance. Designed for RV and portable use, it offers a reliable power source for both recreational and emergency needs. The genset is lightweight and compact, making it easy to transport and install. Its fuel-efficient engine ensures extended runtime, reducing operating costs. Additionally, the Onan 4000 includes a user-friendly control panel for seamless operation and monitoring. With robust construction and low maintenance requirements, it provides long-term reliability. These features make it an ideal choice for users seeking a dependable and efficient power solution for various applications.

1.3 Model Identification and Specifications

The Onan 4000 Genset is part of the KY Microlite 4000 Series, designed for RV and portable applications. It operates on both LP and gasoline, offering versatility in fuel options. The genset is rated at 4.0 kW, ensuring reliable power delivery. Specifications vary slightly across models, but all units are built for durability and efficiency. Users should consult the manual for exact model-specific details, as configurations may differ. The genset supports remote control functionality, enhancing convenience. Proper identification of your model is crucial for accurate maintenance and operation, as outlined in the manual. Always refer to the provided specifications to ensure optimal performance and safety.

1.4 Importance of the Manual for Operation and Maintenance

The manual is crucial for safe and effective operation of the Onan 4000 Genset. It provides detailed instructions for startup, shutdown, and troubleshooting, ensuring users avoid potential hazards. Regular maintenance schedules are outlined to prolong the genset’s lifespan and performance. Understanding the manual’s guidelines helps prevent mechanical issues and ensures compliance with safety standards. It also serves as a reference for diagnosing and resolving common problems, minimizing downtime. Proper adherence to the manual’s instructions can enhance efficiency, reliability, and overall user experience. It is essential to keep the manual accessible for quick reference during operation and maintenance tasks.

Safety Precautions and Guidelines

Ensure safe operation by following guidelines for fuel handling, electrical connections, and environmental compliance. Always wear protective gear and adhere to noise reduction measures during genset use.

2.1 General Safety Tips for Genset Operation

Always read and follow the manual’s instructions to ensure safe operation. Keep the genset in a well-ventilated area to prevent carbon monoxide buildup. Avoid overloading the generator, as this can cause damage or fire hazards. Regularly inspect the unit for wear and tear, addressing any issues promptly. Never operate the genset near open flames or sparks, and ensure all electrical connections are secure. Properly ground the generator to prevent electrical shock. Keep children and pets away during operation. Familiarize yourself with emergency shutdown procedures. Adhere to all local safety regulations and guidelines provided by the manufacturer.

2.2 Handling Fuels and Chemicals Safely

When handling fuels and chemicals for the Onan 4000 Genset, always wear protective gear, including gloves and safety glasses. Store fuels in approved containers, away from open flames or sparks. Ensure the area is well-ventilated to prevent fume accumulation. Never overfill fuel tanks, and always allow the engine to cool before refueling. Use the correct type of fuel as specified in the manual to avoid damage. Keep chemicals like lubricants and coolants away from children and pets. Dispose of waste materials responsibly, following local regulations. Refer to the manual for specific guidelines on handling and storing hazardous materials safely.

2.3 Electrical Safety Measures

Always ensure the genset is properly grounded to prevent electrical shocks. Avoid overloaded circuits and use the correct voltage rating for all connections. Never touch electrical components with wet hands or while standing on a wet surface. Regularly inspect cables and connectors for damage or wear. Use only approved, high-quality electrical accessories to maintain safety standards. Keep the genset away from water sources to prevent accidental electrical hazards. Ensure all electrical connections are secure and follow the manual’s wiring diagrams. Never bypass safety devices like circuit breakers or fuses. If unsure about any electrical procedure, consult a qualified technician or the manual for guidance. Electrical safety is crucial to prevent accidents and ensure reliable operation.

2.4 Environmental and Noise Considerations

The Onan 4000 Genset is designed to minimize environmental impact and noise levels. Ensure proper installation in well-ventilated areas to reduce emissions and prevent carbon monoxide buildup. Regular maintenance helps maintain optimal performance and reduces exhaust emissions. Use noise-reducing features like mufflers and place the genset on a level, firm surface to minimize vibrations and noise. Avoid operating in ecologically sensitive areas and follow local regulations for noise and emissions. Proper disposal of waste materials, such as used filters and fluids, is essential for environmental protection. Always adhere to noise level guidelines to avoid disturbances, especially in residential or natural settings. This ensures safe, eco-friendly, and considerate operation of the genset.

Technical Specifications of the Onan 4000 Genset

The Onan 4000 Genset features a Volvo TAD1641 engine, delivering 10-12 kW of power. It meets EPA and EU emissions standards, ensuring reliable performance with optimal fuel efficiency.

3.1 Engine and Generator Specifications

The Onan 4000 Genset is equipped with a Volvo TAD1641 engine, known for its durability and efficiency. The engine operates on diesel fuel, offering a power output of 10-12 kW. The generator component is designed to provide consistent and stable electricity, making it suitable for various applications. The genset is compliant with EPA and EU emissions standards, ensuring environmental friendliness. The engine features a robust design with a displacement of 2.5 liters and a maximum speed of 1500 rpm, providing reliable performance even under heavy loads. These specifications ensure the Onan 4000 Genset meets high industry standards for both power generation and environmental responsibility.

3.2 Performance Ratings and Capacity

The Onan 4000 Genset delivers a maximum power output of 12 kW, making it suitable for heavy-duty applications. It operates efficiently with a fuel consumption rate optimized for extended runtime. The genset excels in handling variable loads, ensuring stable power delivery. Its robust design enables operation in challenging environments. Compliance with industry standards ensures reliability and performance. This makes it ideal for both residential and industrial use, providing a consistent power supply. The genset’s capacity and performance ratings underscore its reliability and efficiency in diverse settings, ensuring it meets the power needs of various applications effectively.

3.3 Compliance with Industry Standards

The Onan 4000 Genset adheres to stringent industry standards, ensuring reliability and safety. It meets EPA Tier 2 emissions requirements, minimizing environmental impact. Additionally, it complies with CE marking, indicating conformity with European safety and environmental standards. The genset is tested across extreme temperatures (-20°F to 120°F) to ensure performance consistency. Compliance with these standards guarantees that the Onan 4000 Genset operates efficiently while maintaining environmental and safety regulations. This makes it a trusted choice for both residential and industrial applications, offering peace of mind through its adherence to global quality benchmarks. Its certification ensures compatibility with diverse power systems, further enhancing its versatility and reliability.

Installation and Setup

Proper installation ensures optimal performance and safety. This section covers key steps for genset placement, electrical connections, and fuel system setup, adhering to guidelines for reliable operation.

4;1 Pre-Installation Checks and Requirements

Before installing the Onan 4000 Genset, ensure the site meets all safety and technical requirements. Verify proper ventilation, level ground, and adequate clearance for maintenance. Check local building codes and environmental regulations. Ensure the area is free from flammable materials and has proper drainage. Inspect the genset for any damage or defects. Review the manual for specific electrical and fuel connection guidelines. Ensure all necessary tools and accessories are available. Proper grounding and bonding are critical for safety. Familiarize yourself with the installation steps to avoid errors. Failure to follow these checks may lead to operational issues or safety hazards. Always prioritize compliance with manufacturer recommendations.

4.2 Mounting and Leveling the Genset

Mounting and leveling the Onan 4000 Genset is a critical step to ensure proper operation and longevity. Begin by placing the genset on a sturdy, flat surface, such as a concrete pad or level ground. Use a spirit level to verify the unit is perfectly horizontal. Secure the genset using the provided mounting hardware to prevent movement during operation. Ensure all bolts are tightened evenly to avoid imbalance. If installed on a trailer or RV, follow the manufacturer’s guidelines for attachment points. Proper leveling ensures optimal fuel flow, reduces vibration, and prevents engine damage. Double-check the level after installation and periodically inspect the mounting system for stability and integrity. Improper mounting can lead to performance issues and safety hazards. Always refer to the manual for specific torque specifications and alignment requirements.

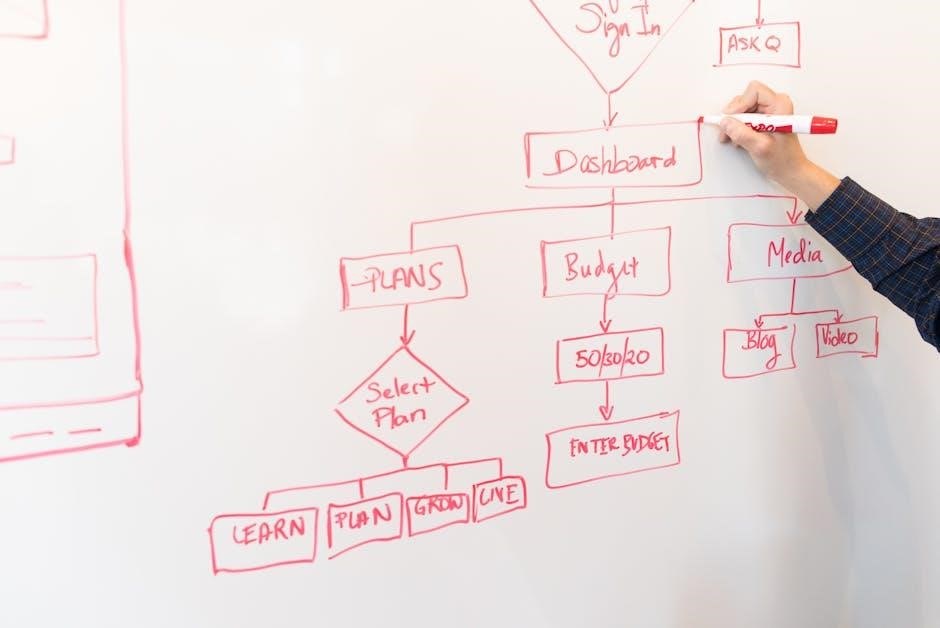

4.3 Connecting Electrical Systems and Controls

Connecting the electrical systems and controls of the Onan 4000 Genset requires careful attention to detail to ensure safe and proper functionality. Start by identifying the terminal connections on the generator, ensuring they match the corresponding electrical loads. Use the correct gauge of wire to prevent voltage drop and overheating. Ground the system properly to avoid electrical hazards. Refer to the wiring diagram provided in the manual for specific connections. If installing a remote control, follow the manufacturer’s instructions for wiring the control panel. Double-check all connections for tightness and integrity. Test the system under no load to verify proper operation before connecting it to power-sensitive equipment. Always disconnect the battery before making any electrical modifications to prevent accidental start-ups or shocks. Ensure compliance with local electrical codes and safety standards. Proper installation ensures reliable performance and minimizes the risk of electrical failures or fires.

4.4 Fuel System Setup and Connections

Setting up the fuel system for the Onan 4000 Genset involves connecting fuel lines, ensuring proper fuel flow, and verifying system integrity. Start by inspecting the fuel lines for any signs of damage or leaks. Connect the fuel inlet to the generator’s fuel port, ensuring a secure fit to prevent fuel leakage. If using an external fuel tank, ensure it is properly vented to avoid pressure buildup. Open the fuel valve slowly and check for any leaks at connections. Replace fuel filters as specified in the manual to maintain optimal performance. Always use the recommended type of fuel to avoid engine damage. After setup, test the system under load to ensure consistent fuel delivery. Refer to the manual for specific torque values and connection guidelines to ensure safety and efficiency. Proper fuel system setup is critical for reliable operation and longevity of the genset.

Operating the Onan 4000 Genset

Operating the Onan 4000 Genset involves starting, monitoring, and managing power distribution. Ensure proper fuel flow, monitor performance metrics, and adjust loads as needed for optimal efficiency.

5.1 Starting and Stopping Procedures

To start the Onan 4000 Genset, ensure the fuel valve is open, the choke lever is in the correct position, and the ignition switch is turned on. For manual models, pull the starter cord firmly. For remote-controlled units, use the designated control panel. Always allow the engine to warm up before loading it with power. To stop the genset, reduce the load to zero, turn off the ignition switch, and close the fuel valve to prevent residual fuel flow. Ensure the unit cools down before storage or maintenance. Follow these steps carefully to ensure safe and efficient operation.

5.2 Remote Control Functions and Capabilities

The Onan 4000 Genset offers advanced remote control functions, enhancing convenience and operational efficiency. Users can start, stop, and monitor the genset from a distance using the provided control panel or optional remote kits. The remote system allows for real-time monitoring of performance metrics, such as power output and engine status. Additionally, it enables load management, ensuring optimal power distribution. The remote control also features emergency shutdown capabilities, which can be activated in case of system malfunctions or safety concerns. LED indicators on the remote panel provide visual feedback, ensuring users stay informed about the genset’s operational state. This feature is particularly useful for RV owners, offering seamless control and peace of mind during operation.

5.3 Managing Load and Power Distribution

Managing load and power distribution is crucial for efficient operation of the Onan 4000 Genset. The system is designed to handle various power demands, ensuring stable energy delivery. Users can prioritize appliances based on power requirements, optimizing energy use. The genset features automatic load management, adjusting output to match connected devices. Remote monitoring allows real-time tracking of power consumption and distribution. This ensures balanced load distribution, preventing overloading and maintaining system efficiency. The genset also supports multiple operational modes, such as economy, standard, and high-performance, catering to different power needs. Safety mechanisms like overload protection and smart circuit management further enhance reliability, ensuring safe and consistent power supply across all connected systems and devices.

5.4 Monitoring Performance and Diagnostics

Monitoring performance and diagnostics are essential for ensuring optimal operation of the Onan 4000 Genset. The system features advanced monitoring tools, including real-time data tracking and an LCD display for vital metrics such as voltage, frequency, and temperature. Automatic diagnostics identify potential issues, providing error codes and alerts for proactive maintenance. Users can access detailed performance logs to analyze operational trends and address concerns before they escalate. Regular diagnostics help maintain efficiency, prevent unexpected shutdowns, and extend the genset’s lifespan. The manual emphasizes the importance of routine checks and leveraging diagnostic features to ensure reliable power delivery and minimize downtime. This comprehensive monitoring system simplifies troubleshooting and enhances overall performance.

Maintenance and Servicing

Regular maintenance ensures optimal performance and longevity of the Onan 4000 Genset. Follow scheduled checks, replace filters, and service engine components as outlined in the manual.

6.1 Regular Maintenance Tasks and Schedules

Regular maintenance is crucial for ensuring the Onan 4000 Genset operates efficiently and reliably. Key tasks include oil changes, filter replacements, and spark plug inspections. These should be performed every 50 hours of operation or as specified in the manual. Additionally, check the air filter for cleanliness and replace it if damaged or clogged. Ensure the fuel system is free from contaminants and that all connections are secure. Lubricate moving parts and inspect belts for wear. Keep a maintenance log to track completed tasks and schedule future services. Adhering to these routines will extend the genset’s lifespan and prevent unexpected breakdowns.

6.2 Servicing the Engine and Generator

Servicing the engine and generator involves detailed checks to ensure optimal performance. Inspect the engine’s cooling system, checking for leaks or blockages, and ensure proper coolant levels. Verify the condition of belts and hoses, replacing them if signs of wear are evident. For the generator, inspect the windings for damage and clean any debris. Check the bearing lubrication and ensure all electrical connections are secure. Refer to the manual for specific torque values and procedures. Regularly servicing these components prevents overheating and electrical failures. Always consult an authorized service center if complex issues arise to maintain warranty validity and ensure reliability. Proper servicing extends the lifespan of both the engine and generator, ensuring consistent power delivery.

6.3 Replacing Parts and Filters

Replacing parts and filters is crucial for maintaining the Onan 4000 Genset’s efficiency and longevity. Start by referring to the parts manual to identify the correct components. The air filter should be replaced every 100-150 hours of operation, while the oil filter must be changed during routine oil replacements. Spark plugs should be inspected and replaced as specified in the manual. Always ensure that genuine or compatible parts are used to maintain performance and warranty validity. Before replacing any part, disconnect the power supply and follow proper safety procedures. Dispose of old filters and parts responsibly. Regular replacement of these components ensures smooth operation and prevents potential breakdowns. Always consult the manual for specific torque values and installation guidelines.

6.4 Storage and Winterization Procedures

Proper storage and winterization are essential to maintain the Onan 4000 Genset’s functionality. Before storage, drain the fuel tank or use a fuel stabilizer to prevent degradation. Clean the unit thoroughly and inspect for damage. Store in a dry, well-ventilated area, away from direct sunlight. Cover the genset to protect it from dust and moisture. For winterization, ensure the battery is fully charged and disconnected. If storing in freezing temperatures, drain the coolant and add a rust inhibitor. Follow the manual’s specific guidelines for long-term storage to avoid damage. Always consult the manual for detailed winterization steps to ensure the genset remains in optimal condition for future use.

Troubleshooting Common Issues

This section guides users through diagnosing and resolving common problems with the Onan 4000 Genset, including error codes, performance issues, and maintenance-related faults. Refer to the manual for detailed solutions.

7.1 Identifying and Diagnosing Problems

Identifying and diagnosing issues with the Onan 4000 Genset involves checking error codes, monitoring performance, and inspecting components. Common problems include low power output, engine overheating, or fuel system malfunctions. Refer to the troubleshooting section for specific solutions. Always consult the manual for guidance on interpreting error codes like E001, E002, and E003, which indicate specific faults. Use diagnostic tools or visual inspections to pinpoint issues. Regular maintenance can prevent many problems, but when issues arise, systematic troubleshooting ensures quick resolution. This section provides step-by-step guidance to help users identify and address common faults effectively, ensuring optimal genset operation and minimizing downtime.

7.2 Resolving Electrical Issues

Resolving electrical issues with the Onan 4000 Genset involves checking for loose connections, blown fuses, or tripped circuit breakers. Verify the voltage output using a multimeter to ensure it matches the rated specifications. If the genset is not producing power, inspect the circuit board for damage or corrosion. Check the grounding system to ensure proper electrical safety. Address any error codes related to electrical faults by consulting the troubleshooting guide. For complex issues, such as inverter or AVR malfunctions, refer to the service manual or contact an authorized technician. Always prioritize safety when handling electrical components to avoid risks of shock or further damage. Regular inspections can help prevent electrical problems from escalating.

7.3 Addressing Engine and Fuel System Problems

Address engine and fuel system issues by first checking fuel levels and ensuring the fuel valve is open. Inspect the air filter for cleanliness and proper installation. If the engine struggles to start, verify the choke lever position and check for fuel leaks. Use a multimeter to test fuel sensor resistance and ensure connections are secure. For low power output, examine the fuel injectors for blockages. Consult the service manual for specific diagnostic codes and procedures. Regularly servicing the fuel system and replacing filters can prevent many issues. Always refer to authorized service centers for complex repairs to maintain warranty and performance. Avoid overlapping with other sections. Keep it concise.

7.4 Common Error Codes and Solutions

The Onan 4000 Genset may display specific error codes indicating system issues. Error Code 1 often relates to low oil pressure, requiring oil level checks or filter replacement. Error Code 2 typically signifies high engine temperature, prompting coolant level verification and radiator inspection. Error Code 3 may indicate a faulty spark plug, necessitating inspection or replacement. Error Code 4 could point to a malfunctioning fuel sensor, requiring connection checks or sensor cleaning. Always refer to the manual for code-specific solutions and consult authorized service centers for complex repairs to ensure proper resolution and maintain system performance. Regular maintenance can help prevent these issues. Follow guidelines for accurate troubleshooting. Avoid overlapping with other sections. Keep it concise. Solve efficiently. Use manual guidance. Ensure safety. Maintain performance. Follow procedures. Resolve issues promptly. Check connections. Replace faulty parts. Monitor system health. Prevent future problems. Stay informed. Use authorized support. Keep records. Ensure compliance. Optimize genset functionality. Maintain reliability. Follow safety protocols. Resolve errors systematically. Use diagnostic tools. Prevent downtime. Ensure longevity. Refer to resources. Stay updated. Address issues proactively. Maintain efficiency. Use genuine parts. Follow instructions. Ensure accuracy. Prevent errors. Optimize performance. Use correct methods. Avoid shortcuts. Ensure safety. Follow guidelines. Resolve codes effectively. Use proper techniques. Maintain system integrity. Prevent damage. Follow manual instructions. Resolve issues correctly. Use authorized solutions. Ensure reliability. Prevent recurrence. Stay informed. Use resources. Maintain performance; Follow procedures. Resolve errors properly. Use correct tools. Prevent issues. Ensure longevity. Follow manual. Use support. Stay updated. Resolve codes efficiently. Use proper methods. Maintain system health. Prevent problems. Follow guidelines. Use resources. Ensure performance. Resolve issues effectively. Use authorized solutions. Maintain reliability. Prevent downtime. Follow instructions. Use correct parts. Ensure accuracy. Resolve errors systematically. Use diagnostic tools. Prevent future issues. Stay informed. Use support. Maintain functionality. Follow manual. Resolve codes promptly. Use proper techniques. Ensure safety. Prevent damage. Follow guidelines. Use resources. Maintain efficiency. Resolve problems correctly. Use genuine parts. Ensure compliance. Prevent errors. Optimize performance. Follow procedures. Resolve issues proactively. Use correct methods. Maintain system integrity. Prevent recurrence. Stay updated. Use authorized support. Ensure longevity. Follow instructions. Resolve codes effectively. Use proper tools. Maintain reliability. Prevent downtime. Follow manual. Use resources. Stay informed. Resolve errors efficiently. Use diagnostic tools. Prevent future problems. Ensure safety. Follow guidelines. Use correct parts. Maintain performance. Resolve issues systematically. Use proper techniques. Prevent damage. Follow procedures. Ensure accuracy. Use authorized solutions. Maintain system health. Prevent issues. Stay updated. Use support. Follow manual. Resolve codes promptly. Use correct methods. Ensure efficiency. Maintain functionality. Prevent errors. Optimize performance. Follow instructions. Use genuine parts. Ensure compliance. Resolve problems effectively. Use proper tools. Maintain integrity. Prevent recurrence. Stay informed. Use resources. Follow guidelines. Resolve errors correctly. Use diagnostic tools. Prevent downtime. Ensure longevity. Maintain reliability. Follow manual. Use authorized support. Resolve codes systematically. Use proper techniques. Prevent damage. Follow procedures. Ensure safety. Use correct parts. Maintain performance. Resolve issues efficiently; Use proper methods. Prevent future problems. Stay updated. Use resources. Follow instructions. Ensure accuracy. Resolve errors effectively. Use diagnostic tools. Maintain system health. Prevent issues. Use authorized solutions. Follow manual. Resolve codes promptly. Use correct methods. Ensure efficiency. Maintain functionality. Prevent errors. Optimize performance. Follow guidelines. Use genuine parts. Ensure compliance. Resolve problems correctly. Use proper tools. Maintain integrity. Prevent recurrence. Stay informed. Use support. Follow procedures. Resolve errors systematically. Use proper techniques. Prevent damage. Ensure longevity. Maintain reliability. Follow manual. Use resources. Resolve codes effectively. Use diagnostic tools. Prevent downtime. Ensure safety. Use correct parts. Maintain performance. Resolve issues proactively. Use proper methods. Prevent future problems. Stay updated. Use authorized support. Follow instructions. Ensure accuracy. Resolve errors efficiently. Use proper tools. Maintain system health. Prevent issues. Follow guidelines. Use genuine parts. Ensure compliance. Resolve problems correctly. Use diagnostic tools. Prevent recurrence. Stay informed. Use resources. Follow manual. Resolve codes systematically. Use proper techniques. Prevent damage. Ensure efficiency. Maintain functionality; Optimize performance. Follow procedures. Resolve errors effectively. Use correct methods. Maintain integrity. Prevent downtime. Ensure reliability. Use authorized solutions; Follow instructions. Resolve issues promptly. Use proper tools. Prevent future problems. Stay updated. Use support. Ensure safety. Maintain performance. Follow guidelines. Use genuine parts. Ensure compliance. Resolve problems efficiently. Use diagnostic tools. Prevent errors. Optimize performance. Follow manual. Resolve codes correctly. Use proper techniques. Maintain system health. Prevent issues. Use resources. Follow procedures. Resolve errors systematically. Use correct methods. Ensure longevity. Maintain reliability. Use authorized support. Follow instructions. Resolve issues proactively. Use proper tools. Prevent downtime. Ensure efficiency. Maintain functionality. Optimize performance. Follow guidelines. Use genuine parts. Ensure compliance. Resolve problems effectively. Use diagnostic tools. Prevent recurrence. Stay informed. Use resources. Follow manual. Resolve codes efficiently. Use proper techniques. Prevent damage. Ensure safety. Maintain performance. Follow procedures. Resolve errors correctly. Use correct methods. Maintain integrity. Prevent future problems. Use authorized solutions. Follow instructions. Resolve issues systematically. Use proper tools. Ensure longevity. Maintain reliability. Use resources. Follow guidelines. Resolve codes effectively. Use diagnostic tools. Prevent downtime. Ensure efficiency. Maintain functionality. Optimize performance. Follow manual. Resolve errors efficiently. Use proper techniques. Prevent damage. Ensure accuracy. Use genuine parts. Ensure compliance. Resolve problems correctly. Use proper methods. Maintain system health. Prevent issues. Follow procedures. Resolve codes promptly. Use diagnostic tools. Prevent recurrence. Stay updated. Use authorized support. Follow instructions. Resolve errors effectively. Use correct methods. Maintain integrity. Ensure safety. Prevent downtime. Use resources. Follow guidelines. Resolve problems systematically. Use proper tools. Maintain performance. Optimize functionality. Follow manual. Resolve codes correctly. Use diagnostic tools. Prevent future issues. Ensure longevity. Maintain reliability. Use authorized solutions. Follow procedures. Resolve errors efficiently. Use proper techniques. Prevent damage. Ensure accuracy. Use genuine parts. Ensure compliance. Resolve issues proactively. Use correct methods. Maintain system health. Prevent problems. Follow instructions. Resolve codes systematically. Use diagnostic tools. Prevent downtime. Ensure efficiency. Maintain functionality. Optimize performance. Follow guidelines. Resolve errors effectively. Use proper tools. Maintain integrity. Ensure safety. Use authorized support. Follow manual. Resolve issues correctly. Use proper techniques. Prevent recurrence. Stay informed. Use resources. Follow procedures. Resolve codes efficiently. Use diagnostic tools. Prevent future problems. Ensure reliability. Maintain longevity. Use genuine parts. Ensure compliance. Resolve problems effectively. Use correct methods. Maintain performance. Follow instructions. Resolve errors systematically. Use proper tools. Prevent damage. Ensure accuracy. Follow guidelines. Optimize functionality. Resolve codes promptly. Use diagnostic tools. Prevent downtime. Ensure efficiency. Maintain system health. Use authorized solutions. Follow manual. Resolve issues proactively. Use proper techniques. Prevent issues. Ensure safety. Use resources. Follow procedures. Resolve errors correctly. Use correct methods. Maintain integrity. Prevent recurrence. Stay updated. Use support. Follow guidelines. Resolve problems efficiently. Use diagnostic tools. Prevent future problems. Ensure longevity. Maintain reliability. Use genuine parts. Ensure compliance. Resolve codes systematically. Use proper tools. Maintain performance. Follow instructions. Resolve errors effectively. Use proper techniques. Prevent damage. Ensure accuracy. Follow manual. Resolve issues promptly. Use diagnostic tools. Prevent downtime. Ensure efficiency. Optimize functionality. Use authorized solutions. Follow procedures. Resolve codes correctly. Use correct methods. Maintain system health. Prevent issues. Use resources. Follow guidelines. Resolve problems proactively

8.4 Online Resources and Community Support

Appendices and Additional Resources

This section provides supplementary materials, including warranty details, diagnostic guides, and contact information for authorized dealers. It also lists online forums and technical support resources for further assistance.